Menu

-

Motors

-

Electronic Components

- Microcontrollers

- Integrated Circuits

- Transistor

- Thyristor / Triac

- Mosfet

- LED

- Resistor

- Potentiometer

- Trimpot

- Diode

- Capacitor

-

Connectors

- Waterproof Connector

- Military Type Connector

- Mike Connector

- Terminal Block

- Power Connector

- Header

- SMA Connector

- Pogo Pin

- Banana Jack

- Born Jack

- Battery Clip

- Canon Jack

- D-Sub Konnektör

- Dip Switch

- JST Connector

- Tamiya Connector

- Stereo - Mono Jack

- BNC Connector

- Test Clips

- DIN Connector

- Auto Cigarette Lighter Socket

- FFC/FPC Connector

- Other Connectors

- See All

- Crystal Oscillator

- Fuse and Slots

- Joysticks

- Thermal Fuse

- USB Chassis

- Reed Relay

- Transformer & Voltage Converters

- Peltier

- Pastes

- Optocoupler

- Coil

- Other Components

- NTC/PTC

- Relay

- Coolers and Insulators

- Varistor

- See All

-

Arduino

-

Raspberry Pi

-

Robot Kits

-

Educational Kits

-

Sensors

-

3D Printer and Filament

-

Drone and Multicopter

-

Motor Driver Cards

-

Voltage Regulator Boards

-

Relay Cards

-

Buttons and Switches

-

Automation Equipments

-

Screens

-

Electronic Boards

-

Li-po Batteries

- 1S 3.7V Lipo Battery

- 2S 7.4V Lipo Battery

- 3S 11.1V Lipo Battery

- 4S 14.8V Lipo Battery

- 5S 18.5V Lipo Battery

- 6S 22.2V Lipo Battery

- 7S 25.9V Lipo Pil

- 8S 29.6V Lipo Pil

- 12S 44.4V Lipo Battery

- Solid State Lipo Pil

- Airsoft Lipo Battery

- Drone Batteries

- Lipo Chargers

- Lipo Charging and Balancing Boards

- Lipo Indicators

- Lipo Battery Cables

- Lipo Battery Safe Bags

- Lipo Battery Belts

- See All

-

Battery - Lead-Acid Battery - Solar Panels

-

Power Supplies

-

Wireless Communication

- Bluetooth

- WIFI

- RF Module

- GPS/GPRS/GSM

-

Antennas and SMA Connectors

- See All

-

Measurement and Testing Instruments

-

Soldering Iron and Equipment

-

Cables and Converters

-

Copper Plaque and Breadboard

-

Hand Tools and Hardware

-

Speaker and Buzzer

-

Wheels

-

Mechanical Parts

- Outlet

- Contact Us

Close

Cart

.png)

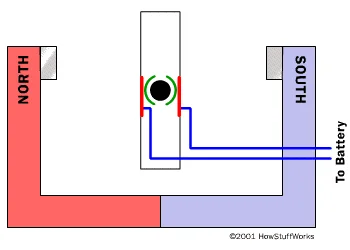

In a typical DC motor, there are permanent magnets on the outside and a rotating armature inside. The permanent magnets are fixed, hence called the stator. The armature rotates, hence called the rotor.

In a typical DC motor, there are permanent magnets on the outside and a rotating armature inside. The permanent magnets are fixed, hence called the stator. The armature rotates, hence called the rotor. With the advent of cheap computers and power transistors, "inverting the motor" and eliminating brushes became possible. In a brushless DC motor (BLDC), you place the permanent magnets on the rotor and move the electromagnets to the stator. Then, you use a computer (connected to high-power transistors) to charge the electromagnets as the shaft rotates. This system has all sorts of advantages:

With the advent of cheap computers and power transistors, "inverting the motor" and eliminating brushes became possible. In a brushless DC motor (BLDC), you place the permanent magnets on the rotor and move the electromagnets to the stator. Then, you use a computer (connected to high-power transistors) to charge the electromagnets as the shaft rotates. This system has all sorts of advantages: