How To Use Brushed DC Motor?

Brushed DC Motor

If you're working on a project involving moving parts, you're probably looking for a motor to provide that motion. We'll explore brushed DC motors, the most popular type of motor used by manufacturers.

The simplest (and most common) type of motor used is the Brushed DC motor. You can find this type of motor everywhere. Brushed DC motors are used in almost all moving toys, to power the vibration function in your phone, and even in cordless drills.

How Brushed DC Motors Work

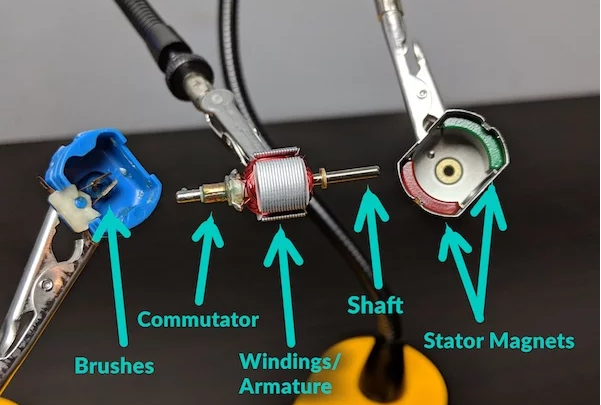

They're simple devices consisting of just a few parts. The outer circumference of the motor housing contains stator magnets. These are permanent magnets with positive on one side and negative on the other. In the middle of the motor, connected to the motor shaft, are at least three wire windings called armatures.

On the opposite side of the shaft from the windings, connected to them by a pair of metal plates, is the commutator. Finally, brushes, which give this type of motor its name, are placed to be in contact with the commutator across from the motor shaft.

The brushes make physical contact with the commutator. When a DC voltage is applied to these brushes, this voltage is transferred to the windings via the commutator in sequence. This electrical input creates a magnetic field around the armature.

The left side of the armature is pushed by the left stator magnet towards the right magnet. The right side of the armature is pushed by the right magnet towards the left.

By continuously changing the polarity of the magnetic field around the armature, the motor shaft starts rotating continuously.

Advantages of Brushed DC Motors

Inexpensive

Brushed DC motors are mass-produced and widely used, making them cheaper than other types of motors.

Easy to Control

Applying a simple DC voltage makes the motor run. Higher voltage (or a higher PWM duty cycle) makes the motor run faster. Reversing the polarity reverses the direction of rotation. You don't even need a microcontroller to use Brushed DC motors; you can just hook them up to a battery to make them run.

High Starting Torque

Brushed DC motors produce high torque at low speeds. This is important because this high starting torque allows the motor to quickly accelerate even with a load on it.

Disadvantages of Brushed DC Motors

Rapid Wear

Since the brushes physically rub against the commutator while the motor is running, these brushes wear out over time. Therefore, compared to other types of motors, brushed DC motors wear out more quickly.

Electrical Noise

Within a brushed DC motor, electricity jumps between the brush and the commutator. This generates a lot of electrical noise, which can be problematic for microcontrollers or sensors operating in the same system.

Limited Maximum Speed

During operation, there is friction between the brushes and the commutator, causing friction between these two parts. Where there is friction, there is heat. Brushed DC motors have a limited maximum speed because excessive speed can increase the temperature to a damaging level.

Blog Latest Additions

Differences Between Li-ion and Li-Po Batteries: Which Battery is Suitable for Which Project?

12.12.2025

MPU-9250: 9-Axis Acceleration Sensor - A Comprehensive Beginner's Guide

28.10.2025

What is ULN2003 ?

13.10.2025

What are Serial Converter Cards (RS232, RS485, TTL)

16.09.2025

What is Peltier and What is its Working Principle?

30.08.2025

Arduino UNO vs Nano vs Mega – Which Should I Choose?

23.07.2025

.png)