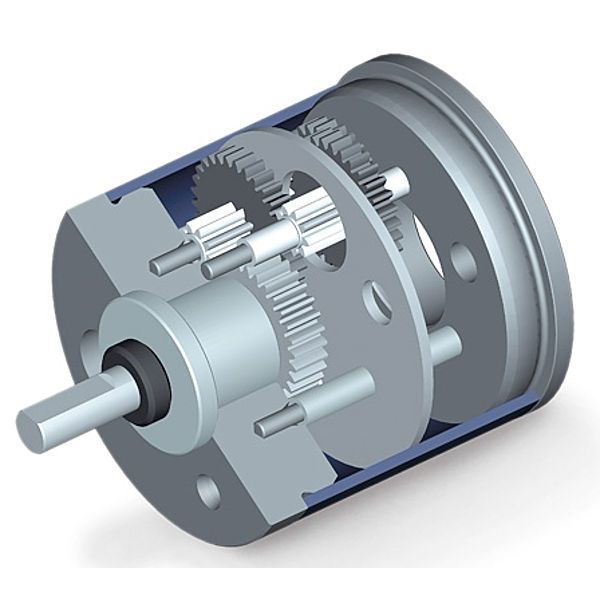

What is a Reduction Gear Motor?

What is a Reduction Gear Motor?

DC motors or 220v AC motors sometimes may not deliver the expected power by themselves. By connecting a reduction gear to these electric motors, their torque can be increased. Thus, with the help of a reduction gear, we obtain high-torque motors without encountering obstacles.

What is a Reduction Gear?

A reduction gear is a gear system used to change the speed-torque ratio in motors. By connecting reduction gears to motors, the speed can be decreased and the torque can be increased. Thus, depending on the project or machine we are working on, we have the opportunity to adjust the motor's speed or power accordingly.

How is Reduction Gear Calculated?

Each pair of gears within the reduction gear represents one stage.

Let's explain with an example:

Assume we have a motor with a power of 20kW and a speed of 4000rpm. (P=20KW, N=4000)

And the gears in the reduction gear are; Z1=10 teeth, Z2=40 teeth

How is Torque Calculated?

First, we need to calculate the input torque. Using the formula P= T1*N1/9550,

T1=9550*20/4000 = 47.75 N-m is found.

In gear pairs working together, the torque (N) ratio is directly proportional to the number of teeth (Z) of the gears.

So, using the formula T1/T2=Z1/Z2, we will find our output torque.

Adjusting our formula: T2=T1*Z2/Z1 from here, the output torque T2= 47.75*40/10= 191 N-m is found.

How is Motor Speed Calculated?

Speed (N) and the number of teeth (Z) on the gear are inversely proportional. Adjusting the formula N1/N2=Z2/Z1:

The output speed N2=4000*10/40 = 1000 rpm is found.

The reduction ratio of the reduction gear is the input speed / output speed:

I: 4000/1000 : found as 4/1.

Share

Blog Latest Additions

The Code of Numbers on Drone Propellers: How to Read Propeller Measurements?

11.02.2026

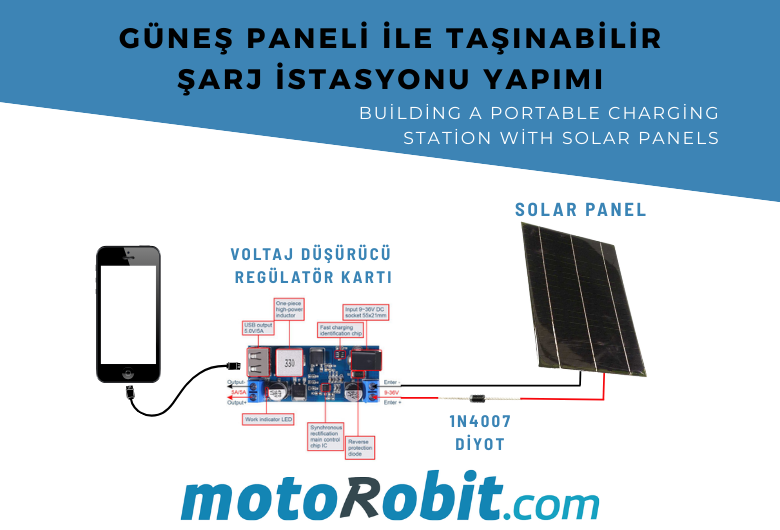

Building a Portable Charging Station with Solar Panels

10.01.2026

Differences Between Li-ion and Li-Po Batteries: Which Battery is Suitable for Which Project?

12.12.2025

MPU-9250: 9-Axis Acceleration Sensor - A Comprehensive Beginner's Guide

28.10.2025

What is ULN2003 ?

13.10.2025

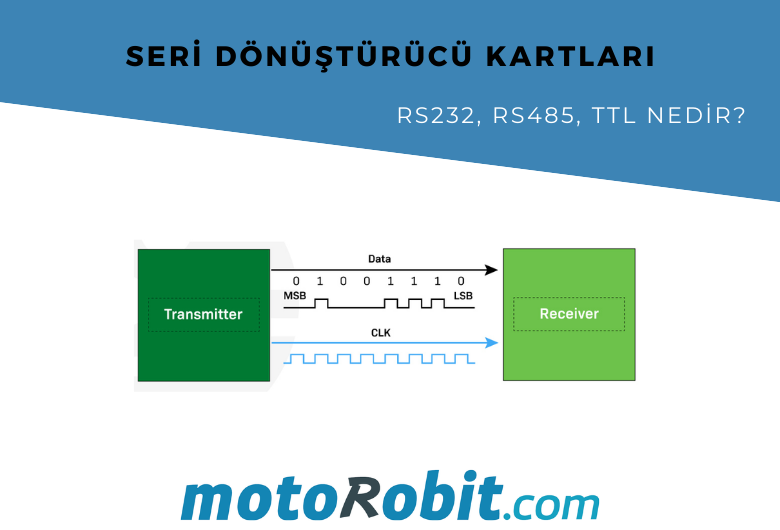

What are Serial Converter Cards (RS232, RS485, TTL)

16.09.2025

.png)