What is an Electromagnetic Valve (Solenoid Valve)?

What is an Electromagnetic Valve (Solenoid Valve)?

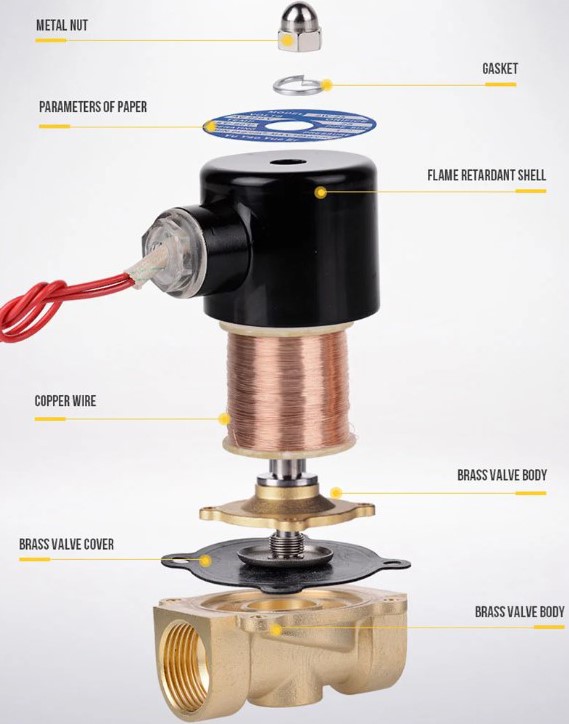

An electromagnetic valve, commonly known as a solenoid valve, is a control device designed to regulate the flow of fluids (gas or liquid) in a pipeline. The operation of the valve is based on an electromagnetic principle, where applying an electric current to a coil (solenoid) generates a magnetic field that moves the mechanism inside the valve, either opening or closing the fluid flow.

How Does a Solenoid Valve Work?

The basic working principle of a solenoid valve is as follows:

When the Coil is Energized: Applying an electric current to the coil generates a magnetic field. This magnetic field moves a movable metal piston (core) inside the valve.

This movement results in the valve opening or closing.

When the core moves, it either opens or blocks the fluid's path.

When the Coil is De-energized: When the electric current is cut off, the magnetic field disappears, and the spring mechanism inside the valve returns the piston to its original position.

In this state, the valve may close or remain open, depending on its type.

Types of Solenoid Valves

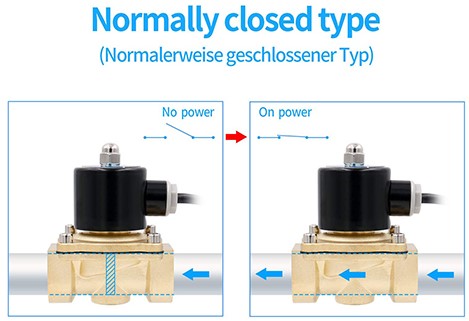

Normally Closed (NC):

The flow path is closed when no electric current is applied.

The valve opens when electric energy is applied.

Normally Open (NO):

The flow path is open when no electric current is applied.

The valve closes when electric energy is applied.

3-Way or 5-Way Valves:

Used in more complex systems to control multiple fluid paths.

Direct-Acting Valves:

Can operate at low pressure and do not require additional pilot pressure to function.

Pilot-Operated Valves:

Used in systems with higher flow capacities and require a minimum system pressure to operate.

Where are Solenoid Valves Used?

Solenoid valves are used in a wide range of applications. Their primary usage areas include:

Industrial Automation:

Fluid control in hydraulic and pneumatic systems.

Factory automation lines.

Agricultural Systems:

Automatic water flow control in irrigation systems.

HVAC Systems:

Fluid management in heating, cooling, and ventilation systems.

Medical Devices:

Gas control in ventilators and other medical devices.

Home Appliances:

Water flow control in washing machines and dishwashers.

Automotive Industry:

In fuel injection systems.

For exhaust gas control.

Petrochemical and Gas Industry:

Control of natural gas and oil flow.

Fire Suppression Systems:

Control of water and gas flow in fire lines.

Points to Consider When Using Solenoid Valves

Proper Valve Selection:

Choose a valve that suits the fluid type (water, gas, oil, etc.), pressure, temperature, and flow rate requirements.

Electrical Connections:

Pay attention to the voltage (AC or DC) and frequency values required for the valve to operate.

Maintenance and Cleaning:

The moving parts inside the valve may get dirty over time. Regular maintenance ensures consistent performance.

Environmental Conditions:

Consider factors like temperature, humidity, and chemical exposure in the valve's environment.

You can explore the various types of electromagnetic valves available on our website here.

Conclusion

Electromagnetic valves are an essential part of automated control systems. With their simple structure, fast response capabilities, and wide range of applications, they are used across various industries. If you plan to use a solenoid valve in your project or system, carefully analyze the valve's technical specifications and system requirements to make the right choice.

The Code of Numbers on Drone Propellers: How to Read Propeller Measurements?

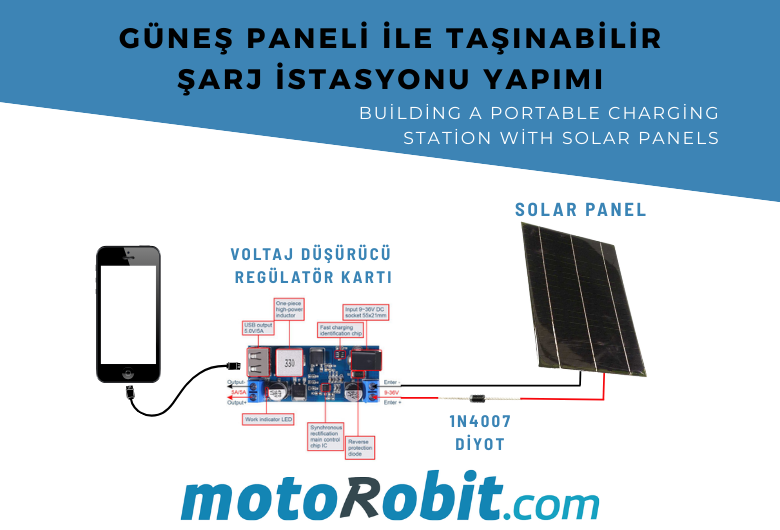

Building a Portable Charging Station with Solar Panels

Differences Between Li-ion and Li-Po Batteries: Which Battery is Suitable for Which Project?

MPU-9250: 9-Axis Acceleration Sensor - A Comprehensive Beginner's Guide

What is ULN2003 ?

.png)