Menu

-

Motors

Motors

-

Electronic Components

Electronic Components

Electronic Components

Electronic Components-

Microcontrollers

Microcontrollers

-

Integrated Circuits

Integrated Circuits

-

Transistor

Transistor

-

Thyristor / Triac

Thyristor / Triac

-

Mosfet

Mosfet

-

LED

LED

-

Resistor

Resistor

-

Potentiometer

Potentiometer

-

Trimpot

Trimpot

-

Diode

Diode

-

Capacitor

Capacitor

-

Connectors

Connectors

- Waterproof Connector

- Military Type Connector

- Mike Connector

- Terminal Block

- Power Connector

- Header

- SMA Connector

- Pogo Pin

- Banana Jack

- Born Jack

- Battery Clip

- Canon Jack

- D-Sub Konnektör

- Dip Switch

- JST Connector

- Tamiya Connector

- Stereo - Mono Jack

- BNC Connector

- Test Clips

- DIN Connector

- Auto Cigarette Lighter Socket

- FFC/FPC Connector

- Other Connectors

- See All

-

Crystal Oscillator

Crystal Oscillator

-

Fuse and Slots

Fuse and Slots

-

Joysticks

Joysticks

-

Thermal Fuse

Thermal Fuse

-

USB Chassis

USB Chassis

-

Reed Relay

Reed Relay

-

Transformer & Voltage Converters

Transformer & Voltage Converters

-

Peltier

Peltier

-

Pastes

Pastes

-

Optocoupler

Optocoupler

-

Coil

Coil

-

Other Components

Other Components

-

NTC/PTC

NTC/PTC

-

Relay

Relay

-

Coolers and Insulators

Coolers and Insulators

-

Varistor

Varistor

- See All

-

-

Arduino

Arduino

-

Raspberry Pi

Raspberry Pi

-

Robot Kits

Robot Kits

-

Educational Kits

Educational Kits

Educational Kits

Educational Kits -

Sensors

Sensors

Sensors

Sensors -

3D Printer and Filament

3D Printer and Filament

3D Printer and Filament

3D Printer and Filament -

Drone and Multicopter

Drone and Multicopter

-

Motor Driver Cards

Motor Driver Cards

Motor Driver Cards

Motor Driver Cards -

Voltage Regulator Boards

Voltage Regulator Boards

Voltage Regulator Boards

Voltage Regulator Boards -

Relay Cards

Relay Cards

-

Buttons and Switches

Buttons and Switches

Buttons and Switches

Buttons and Switches- Metal Button

-

Rocker Switch

Rocker Switch

-

Push Button Switch

Push Button Switch

-

Micro Switch

Micro Switch

-

6X6 Tact Switch

6X6 Tact Switch

-

12X12 Tact Switch

12X12 Tact Switch

-

Toogle Switch

Toogle Switch

-

Slide Switch

Slide Switch

-

Tact Switch

Tact Switch

-

SMD Tact Switch

SMD Tact Switch

-

Game Machine Buttons

Game Machine Buttons

-

Marine Switches and Panels

Marine Switches and Panels

-

Button Box

Button Box

-

Membrane Button

Membrane Button

-

Metal Push Button

Metal Push Button

-

Special Buttons

Special Buttons

-

Elektromanyetik Switch

Elektromanyetik Switch

- See All

-

Automation Equipments

Automation Equipments

-

Screens

Screens

-

Electronic Boards

Electronic Boards

-

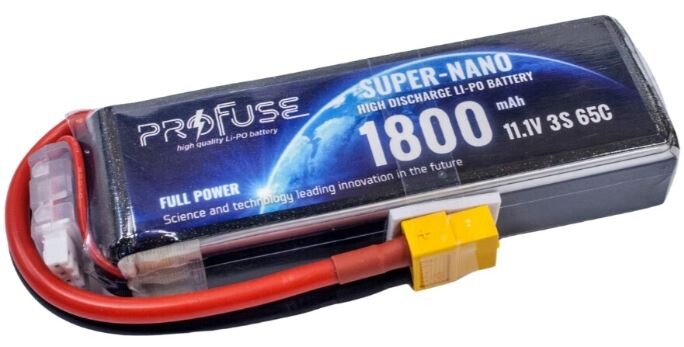

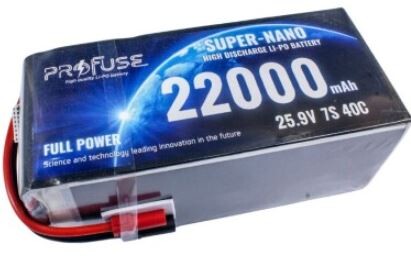

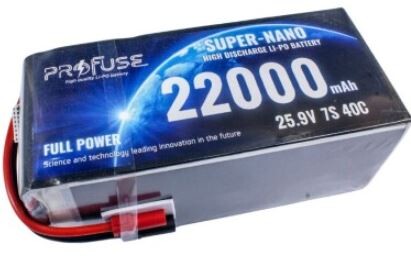

Li-po Batteries

Li-po Batteries

Li-po Batteries

Li-po Batteries-

1S 3.7V Lipo Battery

1S 3.7V Lipo Battery

-

2S 7.4V Lipo Battery

2S 7.4V Lipo Battery

-

3S 11.1V Lipo Battery

3S 11.1V Lipo Battery

-

4S 14.8V Lipo Battery

4S 14.8V Lipo Battery

-

5S 18.5V Lipo Battery

5S 18.5V Lipo Battery

-

6S 22.2V Lipo Battery

6S 22.2V Lipo Battery

-

7S 25.9V Lipo Pil

7S 25.9V Lipo Pil

-

8S 29.6V Lipo Pil

8S 29.6V Lipo Pil

-

12S 44.4V Lipo Battery

12S 44.4V Lipo Battery

-

Solid State Lipo Pil

Solid State Lipo Pil

-

Airsoft Lipo Battery

Airsoft Lipo Battery

-

Drone Batteries

Drone Batteries

-

Lipo Chargers

Lipo Chargers

-

Lipo Charging and Balancing Boards

Lipo Charging and Balancing Boards

-

Lipo Indicators

Lipo Indicators

-

Lipo Battery Cables

Lipo Battery Cables

-

Lipo Battery Safe Bags

Lipo Battery Safe Bags

-

Lipo Battery Belts

Lipo Battery Belts

- See All

-

-

Battery - Lead-Acid Battery - Solar Panels

Battery - Lead-Acid Battery - Solar Panels

Battery - Lead-Acid Battery - Solar Panels

Battery - Lead-Acid Battery - Solar Panels -

Power Supplies

Power Supplies

Power Supplies

Power Supplies -

Wireless Communication

Wireless Communication

Wireless Communication

Wireless Communication-

Bluetooth

Bluetooth

-

WIFI

WIFI

-

RF Module

RF Module

-

GPS/GPRS/GSM

GPS/GPRS/GSM

-

Antennas and SMA Connectors

Antennas and SMA Connectors

- See All

-

-

Measurement and Testing Instruments

Measurement and Testing Instruments

-

Soldering Iron and Equipment

Soldering Iron and Equipment

Soldering Iron and Equipment

Soldering Iron and Equipment -

Cables and Converters

Cables and Converters

-

Copper Plaque and Breadboard

Copper Plaque and Breadboard

Copper Plaque and Breadboard

Copper Plaque and Breadboard -

Hand Tools and Hardware

Hand Tools and Hardware

Hand Tools and Hardware

Hand Tools and Hardware-

Screwdriver

Screwdriver

-

Side Chisel - Pliers

Side Chisel - Pliers

-

Magnet

Magnet

-

Heat Shrink Tubing

Heat Shrink Tubing

-

Tweezers

Tweezers

-

Screw/Nut

Screw/Nut

-

Drills and Drill Bits

Drills and Drill Bits

-

Silicone Gun

Silicone Gun

-

Sprays

Sprays

-

Cable Tie

Cable Tie

-

Organizer Boxes

Organizer Boxes

-

Antistatic ESD Wristband

Antistatic ESD Wristband

-

Chuck

Chuck

-

Tape Types

Tape Types

-

Crimping and Stripping Pliers

Crimping and Stripping Pliers

-

Electronic Nail Drill Set

Electronic Nail Drill Set

-

Other Hand Tools

Other Hand Tools

- See All

-

-

Speaker and Buzzer

Speaker and Buzzer

Speaker and Buzzer

Speaker and Buzzer -

Wheels

Wheels

-

Mechanical Parts

Mechanical Parts

- Outlet

- Contact Us

Close

Cart

.png)

Geared DC Motors

Geared DC Motors

DC Motors Without Gearbox

DC Motors Without Gearbox

Stepper Motors

Stepper Motors

Servo Motors

Servo Motors

AC Motors

AC Motors

Linear Motors

Linear Motors

Solenoid Coil - Valve

Solenoid Coil - Valve

Electromagnetic Valve

Electromagnetic Valve

Vibration Motors

Vibration Motors

DC Motors with Encoder

DC Motors with Encoder

Air and Liquid Pumps

Air and Liquid Pumps

Fans

Fans

Spindle Motors

Spindle Motors

Special Motors

Special Motors

Actuators

Actuators

Gear Boxes

Gear Boxes

Microcontrollers

Microcontrollers

Integrated Circuits

Integrated Circuits

Transistor

Transistor

Thyristor / Triac

Thyristor / Triac

Mosfet

Mosfet

LED

LED

Resistor

Resistor

Potentiometer

Potentiometer

Trimpot

Trimpot

Diode

Diode

Capacitor

Capacitor

Crystal Oscillator

Crystal Oscillator

Fuse and Slots

Fuse and Slots

Joysticks

Joysticks

Thermal Fuse

Thermal Fuse

USB Chassis

USB Chassis

Reed Relay

Reed Relay

Transformer & Voltage Converters

Transformer & Voltage Converters

Peltier

Peltier

Pastes

Pastes

Optocoupler

Optocoupler

Coil

Coil

Other Components

Other Components

NTC/PTC

NTC/PTC

Relay

Relay

Coolers and Insulators

Coolers and Insulators

Varistor

Varistor

Original Arduino Models

Original Arduino Models

Clone Arduino Models

Clone Arduino Models

Arduino Shield

Arduino Shield

Arduino Sets

Arduino Sets

Arduino Modules

Arduino Modules

Arduino Boxes

Arduino Boxes

Raspberry Pi Models

Raspberry Pi Models

Raspberry Pi Electronic Boards

Raspberry Pi Electronic Boards

Raspberry Pi Screens - LCD Display

Raspberry Pi Screens - LCD Display

Raspberry Pi Camera

Raspberry Pi Camera

Raspberry Pi Enclosures

Raspberry Pi Enclosures

Raspberry Pi Accessories

Raspberry Pi Accessories

Raspberry Pi Cables

Raspberry Pi Cables

Wheeled Robot Kits

Wheeled Robot Kits

Tracked Robot Kits

Tracked Robot Kits

Humanoid Robot

Humanoid Robot

Gripper

Gripper

DIY Robot Kits

DIY Robot Kits

Makeblock

Makeblock

Robobloq

Robobloq

Evo Stem Kits

Evo Stem Kits

DIY Training Kits

DIY Training Kits

DIY Electronics Kits

DIY Electronics Kits

Bellrobot

Bellrobot

Object / Line / Distance

Object / Line / Distance

Temperature, Humidity Sensors

Temperature, Humidity Sensors

Accelerometer

Accelerometer

Light, Color

Light, Color

Pressure / Compass

Pressure / Compass

Current / Voltage

Current / Voltage

Signal Generator Modules

Signal Generator Modules

Gas Sensors

Gas Sensors

Weight Sensors

Weight Sensors

Touch Sensors

Touch Sensors

Biometric / Medical

Biometric / Medical

Force / Vibration

Force / Vibration

Sound Sensors

Sound Sensors

Laser

Laser

Magnetic / Encoder

Magnetic / Encoder

Mercury Sensors

Mercury Sensors

Other Sensors

Other Sensors

3D Printer

3D Printer

3D Pen

3D Pen

Filament

Filament

3D Printer Electronic Parts

3D Printer Electronic Parts

3D Printer Mechanical Parts

3D Printer Mechanical Parts

3D Printer Other Parts

3D Printer Other Parts

CNC

CNC

Drone Motors

Drone Motors

Flight Control Boards

Flight Control Boards

Drone Controller 2.4 Ghz

Drone Controller 2.4 Ghz

Brushless Motor Drivers - ESC

Brushless Motor Drivers - ESC

Drone Bodies

Drone Bodies

Drone Kits

Drone Kits

Drone Propellers

Drone Propellers

Other Drone Parts

Other Drone Parts

Ac Motor Drivers

Ac Motor Drivers

Dc Motor Drivers

Dc Motor Drivers

Servo Drivers

Servo Drivers

Stepper Motor Drivers

Stepper Motor Drivers

Step-Down Boards

Step-Down Boards

Step-Up Boards

Step-Up Boards

AC-DC Converter

AC-DC Converter

Optokuplör

Optokuplör

Other Voltage Regulators

Other Voltage Regulators

5V Sequential Relay Cards

5V Sequential Relay Cards

12V Sequential Relay Boards

12V Sequential Relay Boards

Timed Relay Boards

Timed Relay Boards

Temperature and Humidity Adjustable Relay Boards

Temperature and Humidity Adjustable Relay Boards

USB Relay Boards

USB Relay Boards

Solid State Relay Boards

Solid State Relay Boards

IR Controlled Relay Boards

IR Controlled Relay Boards

Other Relay Boards

Other Relay Boards

Push Button Switch

Push Button Switch

Micro Switch

Micro Switch

6X6 Tact Switch

6X6 Tact Switch

12X12 Tact Switch

12X12 Tact Switch

Toogle Switch

Toogle Switch

Slide Switch

Slide Switch

Tact Switch

Tact Switch

SMD Tact Switch

SMD Tact Switch

Game Machine Buttons

Game Machine Buttons

Marine Switches and Panels

Marine Switches and Panels

Button Box

Button Box

Membrane Button

Membrane Button

Metal Push Button

Metal Push Button

Special Buttons

Special Buttons

Elektromanyetik Switch

Elektromanyetik Switch

Buttons and Signal Lamps

Buttons and Signal Lamps

Switches

Switches

Industrial Fans and Filters

Industrial Fans and Filters

Cable Ferrules

Cable Ferrules

Rail Type Power Supplies

Rail Type Power Supplies

Thermocouple

Thermocouple

SKP/FITTING

SKP/FITTING

Busbar Insulator

Busbar Insulator

Digital Display

Digital Display

Touch Screens

Touch Screens

Dot Matrix Display

Dot Matrix Display

Graphic LCD Screens

Graphic LCD Screens

Character LCD Display

Character LCD Display

Keypad

Keypad

Oled LCD Display

Oled LCD Display

Segment Display

Segment Display

TFT Screens

TFT Screens

Development Boards

Development Boards

Microcontroller Programmers

Microcontroller Programmers

Amplifier Boards

Amplifier Boards

Induction Heating Boards

Induction Heating Boards

Modules

Modules

NeoPixel

NeoPixel

Converter Boards

Converter Boards

SMD DIP Converter

SMD DIP Converter

1S 3.7V Lipo Battery

1S 3.7V Lipo Battery

2S 7.4V Lipo Battery

2S 7.4V Lipo Battery

3S 11.1V Lipo Battery

3S 11.1V Lipo Battery

4S 14.8V Lipo Battery

4S 14.8V Lipo Battery

5S 18.5V Lipo Battery

5S 18.5V Lipo Battery

6S 22.2V Lipo Battery

6S 22.2V Lipo Battery

7S 25.9V Lipo Pil

7S 25.9V Lipo Pil

8S 29.6V Lipo Pil

8S 29.6V Lipo Pil

12S 44.4V Lipo Battery

12S 44.4V Lipo Battery

Solid State Lipo Pil

Solid State Lipo Pil

Airsoft Lipo Battery

Airsoft Lipo Battery

Drone Batteries

Drone Batteries

Lipo Chargers

Lipo Chargers

Lipo Charging and Balancing Boards

Lipo Charging and Balancing Boards

Lipo Indicators

Lipo Indicators

Lipo Battery Cables

Lipo Battery Cables

Lipo Battery Safe Bags

Lipo Battery Safe Bags

Lipo Battery Belts

Lipo Battery Belts

18650 Battery and Accessories

18650 Battery and Accessories

Battery

Battery

Battery Slots

Battery Slots

Solar Panel

Solar Panel

Lead-Acid Battery

Lead-Acid Battery

Powerbank

Powerbank

Charging Modules

Charging Modules

Adapters

Adapters

Power Supplies

Power Supplies

Regulated Power Supplies

Regulated Power Supplies

Bluetooth

Bluetooth

WIFI

WIFI

RF Module

RF Module

GPS/GPRS/GSM

GPS/GPRS/GSM

DC Voltaj, Akım ve Watt Ölçer

DC Voltaj, Akım ve Watt Ölçer

AC Voltaj, Akım ve Watt Ölçer

AC Voltaj, Akım ve Watt Ölçer

Digital Multimeter

Digital Multimeter

Clamp Meter

Clamp Meter

LCR Meter

LCR Meter

Oscilloscope

Oscilloscope

IR Thermometer

IR Thermometer

Meger Devices

Meger Devices

Electrical Installation Testing Devices

Electrical Installation Testing Devices

Analog Multimeter

Analog Multimeter

Other Measuring Instruments

Other Measuring Instruments

Probes

Probes

Soldering Iron

Soldering Iron

Soldering Iron Stations

Soldering Iron Stations

Solder Wires

Solder Wires

Solder & Soldering Iron Pumps

Solder & Soldering Iron Pumps

Soldering Iron Stand

Soldering Iron Stand

Flux

Flux

Solder Pastes

Solder Pastes

Soldering Iron Tips

Soldering Iron Tips

Jumper Cables

Jumper Cables

Installation Cables

Installation Cables

JST Cable

JST Cable

Converter & Jack

Converter & Jack

Computer Cables

Computer Cables

Adjacent and Shielded Cable

Adjacent and Shielded Cable

Flat Cable

Flat Cable

Crocodile Cable

Crocodile Cable

Braided Ground Cable

Braided Ground Cable

Silicone & Glass Fiber Cables

Silicone & Glass Fiber Cables

Breadboard

Breadboard

Copper Plaque

Copper Plaque

Conductive Materials

Conductive Materials

Pnp Paper

Pnp Paper

Screwdriver

Screwdriver

Side Chisel - Pliers

Side Chisel - Pliers

Heat Shrink Tubing

Heat Shrink Tubing

Tweezers

Tweezers

Screw/Nut

Screw/Nut

Drills and Drill Bits

Drills and Drill Bits

Silicone Gun

Silicone Gun

Sprays

Sprays

Cable Tie

Cable Tie

Organizer Boxes

Organizer Boxes

Antistatic ESD Wristband

Antistatic ESD Wristband

Chuck

Chuck

Tape Types

Tape Types

Crimping and Stripping Pliers

Crimping and Stripping Pliers

Other Hand Tools

Other Hand Tools

Buzzer

Buzzer

Microphone

Microphone

Snap-On Wheels

Snap-On Wheels

Terrain Wheels

Terrain Wheels

Caster Wheels

Caster Wheels

Omni Wheels

Omni Wheels

Silicone Wheels

Silicone Wheels

Motor Holders

Motor Holders

Sensor Holders

Sensor Holders

Robot Bodies

Robot Bodies

Coupling

Coupling

Servo HUB

Servo HUB

Spacer / Distance

Spacer / Distance

Plastic Gears

Plastic Gears

Propellers

Propellers